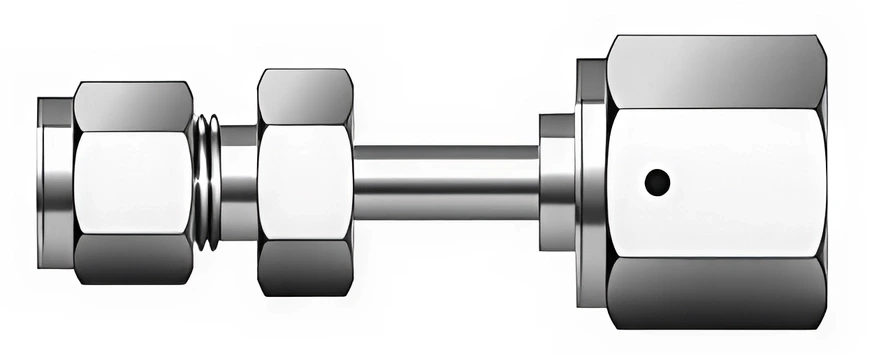

Item# SM4WSC

The SM4WSC offers a reliable solution for 1/4″ head (outer diameter) connections in a welded Lok connector configuration, crafted from 316 Stainless Steel, a corrosion-resistant alloy. Tailored for pressure systems, it ensures precise fluid control in industrial applications, making it ideal for high purity fluid processors. The polished finish supports clean in place instrumentation, perfect for compact, high-purity layouts. Its robust design, featuring sanitary stainless steel fittings, withstands tough conditions effortlessly.

Great for pulp processing and oil and gas transport, it delivers durability and strength. The 316 Stainless Steel resists corrosive gases, temperature shifts, and harsh cleanings, ensuring long-term performance in high purity environments. It integrates seamlessly with standard fittings, minimizing contamination in gas networks.

Installation is straightforward, with a finish that reduces fouling and simplifies maintenance. The SM4WSC maintains a secure weld and seal under pressure, facilitating quick assembly in OEM fluid systems. Its design suits modular process lines, providing consistent adaptability that enhances operational efficiency.

This connector reduces downtime, boosting productivity in high-pressure fluid networks. Compatible with industrial valves, it excels across various applications. For a 1/4″ welded Lok connector, it stands as a trusted solution.

Key Benefits

- Tight Weld: Ensures leak-free connector connections

- Robust Build: Resists wear and harsh conditions

- Clean Design: Supports clean in place instrumentation

- Low Maintenance: Easy to clean and install

- Reliable Flow: Enhances precise fluid control

Typical Applications

- Pulp processing units

- Oil and gas transport

- Chemical processing plants

- Paper production lines

- OEM fluid assemblies

Rely on the SM4WSC for precise engineering and lasting performance, ensuring your high-pressure industrial gas systems operate with confidence.